Phone: +91-22-2532 8223

Level Products

|

FLOAT & BOARD TYPE LEVEL GAUGE |

|

|

|

Float & Board types Level Gauge are used for fulid level measurement in several industries. The Float which is of course the most important element of the instrument. In fact, its structural design, volume displacement, weight, and buoyancy force are all taken into careful consideration when a float is specified for a particular application. |

||

|

|

|

|

|

VIBRATING FORK LEVEL SWITCH |

|

|

|

FUNCTIONS: The electrically stimulated fork vibrates at its mechanically resonance frequency of 125 Hz when the fork is free of the service material. The resonance is caused by the piezoelectric crystals. One of the piezo crystals produces a small voltage which is transmitted to the switching amplifier. If the fork is covered by the bulk material, a damping effect is produced and the piezo crystal does not produce the voltage and the amplifier will switch and a corresponding signal output is actuated. The vibration of the fork has self-cleaning properties. The light deposit on the container wall does not affect the operation of the FC FORK |

||

|

|

|

|

|

MAGNETIC LEVEL INDICATOR |

|

|

|

SERIES : SC / L - 101: Magnetic Level Indicator operates on principles of magnetic field coupling, to provide fluid level information. Float chamber is typically constructed with non magnetic pipe having process connection that matches to the vessel connections. Float size and weight is determined by the process fluid, pressure, temperature and the specific gravity of process fluid. Float contains magnets to provide 360• magnetic flux field. |

||

|

|

|

|

|

TOP MOUNTED LEVEL SWITCH |

||

|

SERIES : SC / L - 401 Operations: SPINK CONTROLS” Manufacture Magnetically Float Operated Top Mounted Level Switch which is intended for controlling one or multi Levels by using Reed Switch. The Unit Consists of Vertical Guide Pipe (Stem), Reed Switches are located, Magnetic Float Sliding over the Stem according to the level in the tank. After passing the float, the reed relay will retain their output state. Various materials of construction are available depending up on Service Condition. Maximum 4 Set points can be given in a Single Level Switch & Maximum stem length will be 3 Meters.

|

||

|

REFLEX LEVELGAUGE

|

Reflex Level Indicator-Model:SC/RLI/401

MODEL SC/RLG/401: Reflex level gauges are designed to detect the difference in refractive indices of vapor and liquid and level detection and can be used in a number of process applications. This glass is flat on the outside and on the inside has a series of prism grooves that face the vapor and liquid space

|

|

|

SIDE MOUNTED LEVEL SWITCH |

|

|

SERIES: SC / L - 501 Description : Side mounted level switch used to control liquid level in vessels containing corrosive or non corrosive liquids. It is used to Pump control, Alarm, Valve control or Level indication. PRINCIPLE: The float lever carries a permanent magnet which is repelled by similar magnet mounted in the switch housing. The magnet having the same pole directed towards each other are separated by a non magnetic diaphragm. The gland less construction offer excellent sealing. |

|

|

ULTRASONIC TYPE LEVEL TRANSMITTER |

|

|

Ultrasonic Level Transmitter (for material & liquid level measurement) is a non-contact reliable & cost-effective material level measuring instrument which is easily installed & maintenance free. It can meet most of the material level measurement requirements without touching the medium. It is a new generation ultrasonic level meter with fully independents property rights developed by the Spink Controls.

|

|

|

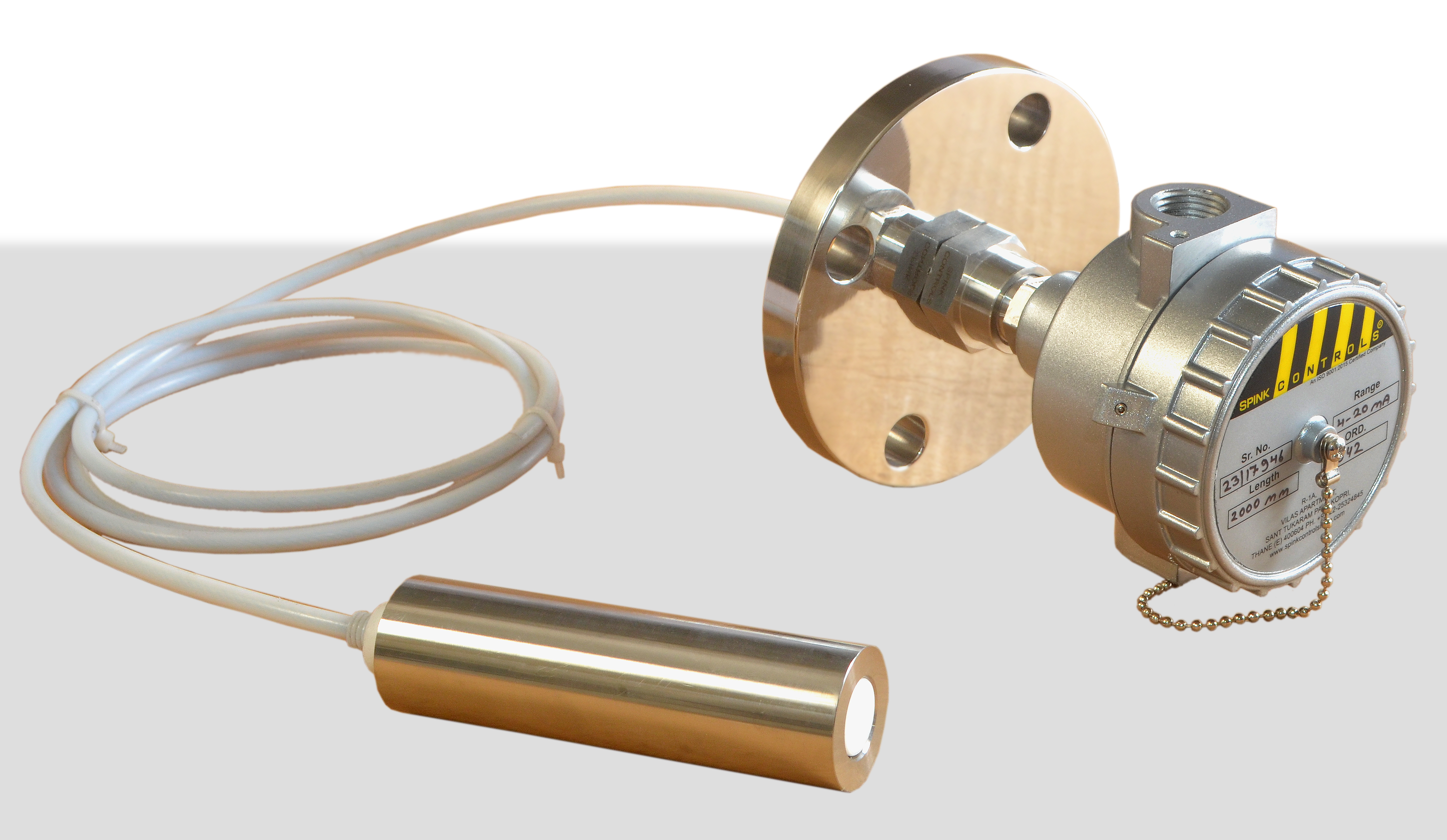

FLOAT OPERATED LEVEL TRANSMITTER |

|

|

SERIES : SC / L-1001 : Float Level Transmitters are ideal for continuous Level monitoring in Water, Diesel, Chemical and Oils for accurate level Measurement. The Output is not affected by liquid type, temperature, Pressure and other physical parameters. The Transmitter is factory calibrated and is ready to use. Construction : Float Level Transmitter consists of non magnetic sealed stem containing series of reed switches and resistor, Float carrying magnet, Mounting adaptor (or flange) and enclosure containing electronics. Consider our Float Level Transmitters for all your continuous liquidlevel monitoring needs like Water, Diesel, Lube oils, Fuels, Chemicals and Petrochemical liquids.

|

|

|

RADAR LEVEL TRANSMITTER |

|

|

PULSE/ FMCW RADAR LEVEL INSTRUMENTS (26 Ghz) SERIES : SC / L - 1101: The Radar Level Meters of CW COMPACT/REMOTE WAVE 26 GHz series are excellent devices for no contact level measurement. The microwave impulses, emitted by the radar?s antenna, travel at speed of light and a part of their energy, reflected by the surface of the medium to be measured, is received by the same antenna. The period of time (flying time) between the emission and the arrival of the impulses, is proportional to the existing distance between the antenna and the surface of the medium to be measured.The electromagnetic wave travels at a very high speed (nanosecond), so it is difficult to identify it: CW COMPACT/REMOTE WAVE 26 GHz Radar Level Meters, thanks to their integrated management system, use a suitable demodulation technology that allows them to identify the period of time between the emission of the impulses and their corrected reception and, consequently, determine and measure the level. The Alphanumeric Display allows the user not just to enter even to display and isolate false echoes.

|

|

Quick Enquiry

Our Channel Partner

CLASSIC FLOW CONTROLS PVT. LTD.

Our Global Channel Partner

STATIC ENGINEERING EQUIPMENTS PVT. LTD.

| Our Solution | Contact Deatils | Our Services | Downloads |

|

303, SIDDHARTH TOWER, MYNOOMAL PATH,KOPRI,THANE(E) 400 603, INDIA

Phone:91-22-2532 8223/24 Email-info@spinkcontrolsindia.com |

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)